Description

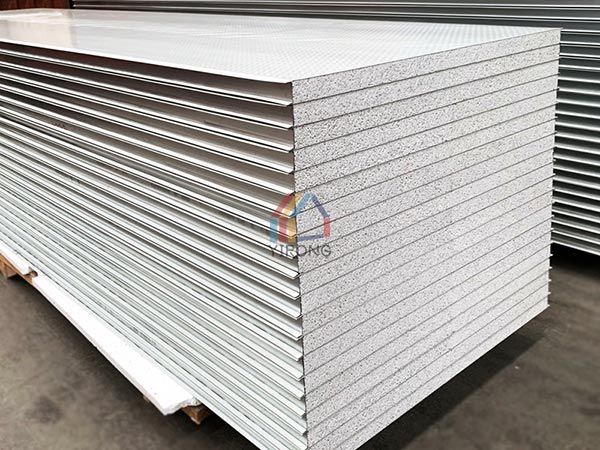

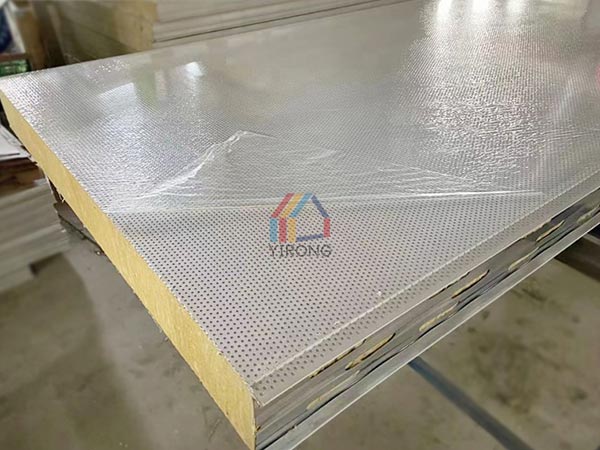

The polystyrene foam plastic sandwich panel is made of color steel sheet as the surface, closed-cell self-extinguishing polystyrene plastic as the core material, and the color steel sheet is pressed by an automatic continuous forming machine and then bonded with a high-strength adhesive. A high-efficiency new composite building material.

The polystyrene foam sandwich panels (EPS sandwich board) are made of raw materials, which are pre – formulated, cured, molded, dried and cut. They can produce foam panels of various thickness. Widely used in construction, thermal insulation, packaging, freezing, daily necessities, industrial casting and other fields. It can also be used in exhibition halls, wardrobes, advertising signs and toy manufacturing. At present, in order to meet the national building energy-saving requirements, it is mainly used in external wall insulation, internal wall insulation and floor heating.

EPS Sandwich Panel have the following characteristics:

① Low cost ② Thermal insulation ③ Sound insulation, fire prevention and waterproofing ④ Beautiful appearance and good overall effect ⑤ Easy installation, strong plasticity, can be cut at will to meet different design needs.

The thickness of polystyrene foam sandwich panels is as follows: 50mm / 75mm / 100mm / 150mm / 200mm.

Panel Thickness | 50mm/75mm/100mm/150mm/200mm (other customized thickness is also acceptable) |

Effective Width | 950mm / 1150mm(wall) ; 950mm(roof) |

Length | Customized as customer’s request, but max 11.8m because of container shipment |

Insulation Core Type | Polystyrene(eps) (Density 8kg/m3~20kg/m3) |

Compound Details | External Layer: PPGI steel sheet, 0.2mm~0.8mm available |

| Middle insulation: EPS panel, 50mm/75mm/100mm/150mm/200mm | |

| Internal Layer: PPGI steel sheet, 0.2mm~0.8mm available | |

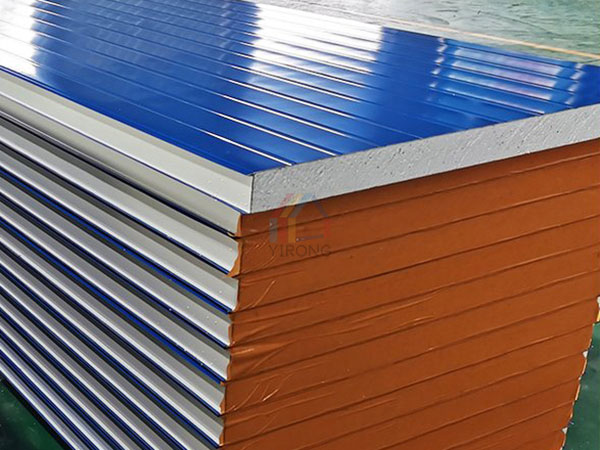

Surface Color | Standard is off-white (RAL9002) or sky blue(RAL5015). Other colors also can be customized but need a quantity bigger than 500sqm. |

Thermal Conductivity | 0.035-0.05W/m.k |

Lifetime | ≥15 years |

Advantages | Lightweight; Waterproof; Good insulation performance with competitive price |

Applications | Widely used as wall/roofing materials for Office; Warehouse; Workshop; Poultry House; Planting Room; Shelters; Cleanroom Etc. |

Application of polystyrene foam sandwich panels

Polystyrene foam sandwich panels are widely used in refrigerators, freezers, refrigerators and so on because of the characteristics of thermal insulation and price friendly to people. Civil buildings are often used in large-span structural roofs, walls, thermal insulation (or fire prevention) plants, purification plants, high and intermediate portfolio housing, container houses, etc..

Features of sandwich panel

1. Construction pre-engineered and fewer components, internationally accepted and meets the building code specifications.

2. Higher energy savings due to low thermal conductivity.

3. Flexibility in design and choosing various options on fascia of panels and colours.

4. All weather proof construction and Maintenance free.

5. These insulated panels gives long lasting value with controlled quality, accuracy & speed of construction and caters for better functionality and application.

Our Advantages