Description

In modern industrial buildings, steel workshop buildings have become the preferred building solution for many enterprises and factories due to their unique structure, wide range of applications, remarkable features and outstanding advantages.

Structural materials

The main structural material of steel workshop building is steel. Steel has become the preferred material for steel structure buildings due to its high strength, corrosion resistance, and reusability. Commonly used steels include Q235, Q345, etc. They not only have high strength, but also have long service life and can maintain stable performance in various environments. In addition, welding materials such as welding wire, welding rods, flux, etc. are also an indispensable part of steel structure buildings. They are used to connect steel to ensure the stability of the entire structure.

Application

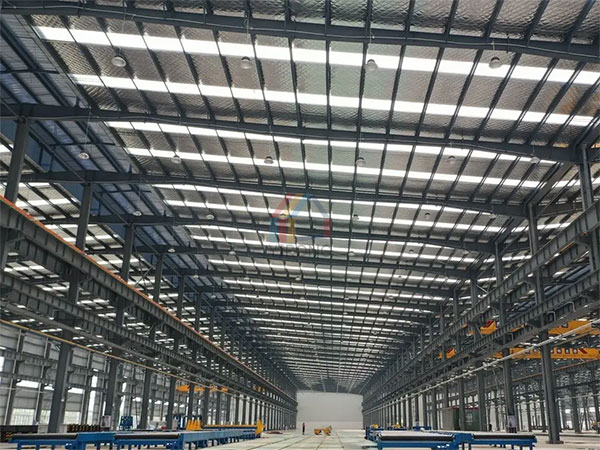

Steel workshop buildings have a very wide range of applications and are suitable for various industrial production needs. From factories and warehouses to office buildings, stadiums, aircraft hangars, etc., steel workshops can be used as the main structure. It is especially suitable for places that require large spans and spacious spaces, such as hangars, stadiums, etc. At the same time, the steel workshop is also suitable for the construction of multi-story or high-rise buildings. Its structure is flexible and can be customized according to specific needs.

Features

The characteristics of steel workshop buildings are mainly reflected in the following aspects:

- Simple structure: The steel workshop building adopts a steel structure system with a clear structure and easy construction and maintenance.

- Fast construction: The steel workshop uses prefabricated components, which makes on-site installation simple and fast, greatly shortening the construction period.

- Light weight and high strength: Steel has the characteristics of lightweight and high strength, making the steel workshop building both light and stable.

- Strong earthquake and wind resistance: Steel has a large elastic modulus and can resist the impact of earthquakes and wind, ensuring the safety of the building.

- Environmental protection and energy saving: Steel is a recyclable material, and using steel to build workshop is in line with the development trend of green buildings. At the same time, steel structure buildings have better thermal insulation performance and can reduce energy consumption.

Advantages

The advantages of steel workshop buildings are mainly reflected in the following aspects:

- High strength and good stability: The tensile and compressive strength of steel are superior to traditional building materials, allowing the steel workshop to withstand the test of natural disasters such as strong winds and earthquakes. At the same time, its structure has good stability and can ensure the continuity and safety of production.

- Flexible space layout: The plasticity of the steel structure makes the workshop design more flexible and can be customized according to the needs of the production process and equipment layout. This flexibility allows the steel shop to meet the production needs of different industries.

- Short construction period: Due to the use of prefabricated components and rapid on-site installation, the construction period of the steel workshop is greatly shortened. This is a huge advantage for companies that urgently need to expand their production scale.

- Low maintenance costs: The steel surface has been specially treated and has good anti-corrosion properties, which can extend the service life of the workshop. At the same time, the replacement and maintenance of steel structure components are relatively simple and convenient, reducing the company’s maintenance costs.

- Excellent environmental performance: The use of steel to build workshop is in line with the development trend of green buildings. During the construction process, the steel structure workshop reduces dependence on natural resources, reduces energy consumption and emissions, and helps enterprises achieve sustainable development.