Description

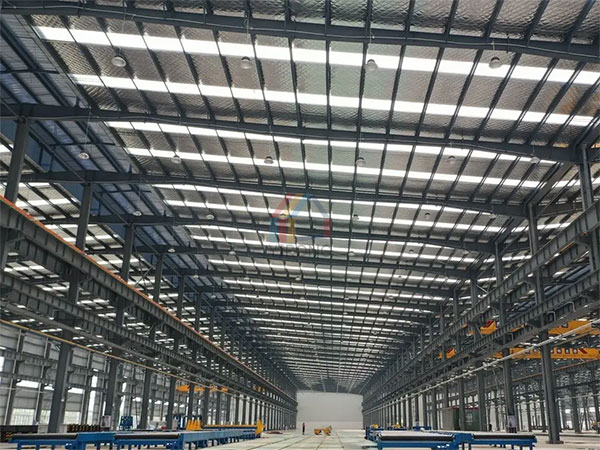

Industrial workshops refer to various houses directly used for production or supporting production, including main workshops, auxiliary houses and auxiliary facilities. All factories in industries, transportation, commerce, construction, scientific research, schools and other units should be included. In addition to the workshop used for production, an industrial plant also includes its ancillary buildings.

In recent years, steel structure workshops have been widely used in industrial factory buildings with their own advantages. Steel structure is a structure mainly made of steel, one of the main types of building structures. The characteristics of steel are high strength, light weight and high rigidity, so it is especially suitable for the construction of large-span and super-high and super-heavy buildings. The steel industrial building has a short construction period and a high degree of industrialization, and can carry out specialized production with a high degree of mechanization.

At present, the commonly used building envelope structures of steel industrial building mainly include: profiled steel plate composite insulation structure, steel frame light plate, and masonry envelope structure.

The profiled steel plate composite thermal insulation structure consists of two layers of formed metal panels and a polymer thermal insulation core directly in the middle of the panels. Finished panels are easy to install, lightweight and efficient. The plate is beautiful in appearance, bright in color and good in overall effect. It integrates load-bearing, thermal insulation, fire prevention and waterproofing, and does not require secondary decoration. It is fast and convenient to install, has short construction period and good comprehensive benefits. efficient and environmentally friendly building materials.

At present, the cores used in color steel sandwich panels mainly include phenolic foam, polyphenylene, rigid polyurethane and rock wool. Phenolic foam has excellent fireproof and thermal insulation properties, which cannot be replaced by other materials. For example, the thermal insulation effect of phenolic foam is more than 2 times that of polystyrene, and its fire resistance is also higher than that of polyurethane. When polyurethane is burned, it will release thick smoke containing hydrogen cyanide. With the emphasis on building fire protection and the introduction of relevant laws, it is believed that phenolic color steel sandwich panels will be widely used.

Light steel structure buildings have many advantages as industrial workshops, such as short construction period, low cost, large span, enviable shape, strong modernity, etc. Therefore, they have been used more and more in the history of modern factory design. However, the fire resistance level of light steel structure buildings is low, and large spaces and large-scale workshops have put forward new requirements for fire compartments. Some of these problems can be solved by technical measures, and some have not yet been perfected.

Fire resistance rating of light steel structure industrial workshop

The load-bearing components of light steel structure industrial factory building are generally steel columns and grids, and the outer surface of the building is covered with colored aluminum-zinc steel plates or aluminum-zinc-plated steel plates. The fire resistance time of its columns and beams is 0.25~0.5 hours, and the fire resistance level of the building is only four (the fire resistance level is lower).