Description

Rock wool board, also known as rock wool thermal insulation decorative board, is an inorganic fiber board made of basalt as the main raw material and processed by high-temperature melting. It has the characteristics of light weight, low thermal conductivity, heat absorption and non combustion.

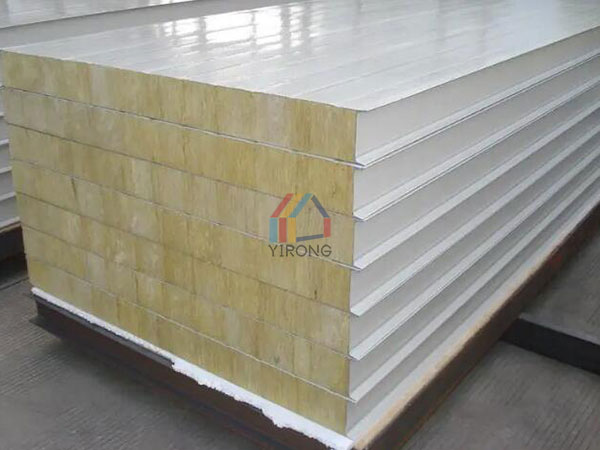

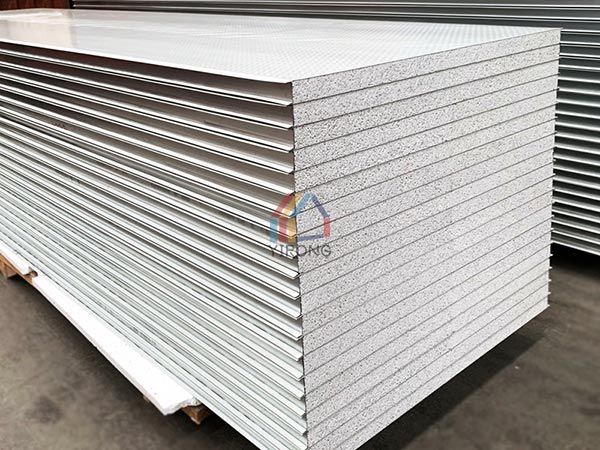

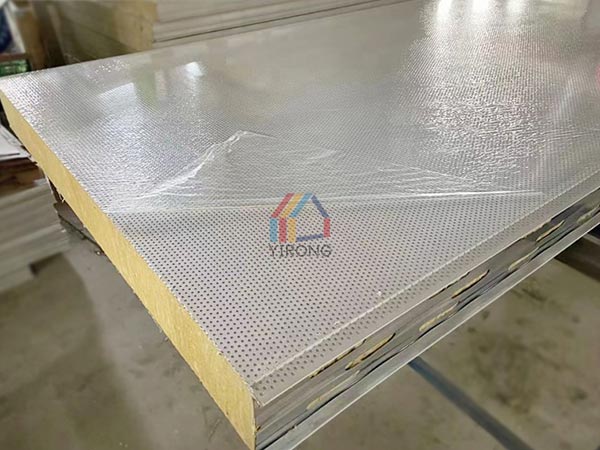

Rock wool sandwich panel is a kind of sandwich panel made from rock wool. Rock wool panel give full play to the unique properties of rock wool core materials, in fire prevention, thermal insulation, sound absorption and other aspects have significant effect. It is suitable for roofing, wall, ceiling and partition of steel structure workshop and simple movable room. In order to increase the strength of rock wool sandwich panel and realize the diversity of connection modes, polyurethane is often used as edge sealing to form polyurethane edge sealing rock wool sandwich panel.

Features of rock wool sandwich panel

Fireproof

①It has the highest fire rating of A1, which can effectively prevent the spread of fire.

②The dimensions are very stable and will not stretch, shrink or deform in a fire.

③High temperature resistance, the melting point is higher than 1000℃.

④ No smoke or burning droplets/debris in fire.

⑤ In a fire, substances and gases that are harmful to the environment will not be released.

Thermal insulation

The outer wall rock wool panel fiber is slender and flexible, and the content of slag ball is low. Therefore, the thermal conductivity is low, and it has an excellent thermal insulation effect.

Sound absorption and noise reduction

Rock wool is an ideal sound insulation material, and a large number of slender fibers form a porous connection structure, which determines that Shida rock wool is an excellent sound absorption and noise reduction material.

Hydrophobicity

The water repellency rate of hydrophobic rock wool products can reach 99.9%; the water absorption rate is extremely low, and there is no capillary penetration.

Moisture resistance

In an environment with high relative humidity, the volume moisture absorption rate of rock wool is less than 0.2%. According to ASTMC1104 or ASTM1104M method, the mass moisture absorption rate is less than 0.3%.

Non-corrosive

Rock wool has stable chemical properties, PH value is 7-8, neutral or weakly alkaline, and is suitable for carbon steel, stainless steel,Metal materials such as aluminum are non-corrosive.

Safety and environmental protection

Rock wool has been tested and does not contain asbestos, CFC, HFC, HCFC and other substances harmful to the environment. Will not be corroded or produce mildew and bacteria.

|

Type

|

Rock Wool Sandwich Panel

|

|

Effective coverage width

|

950mm/1150mm

|

|

Sandwich thickness

|

50mm/75mm/100mm/150mm/200mm

|

|

Surface

|

Prepainted

|

|

Sheet color

|

Customer customize

|

|

density

|

60-120kg/m3

|

|

application

|

prefab house , contaier house ,workshop , warehouse, clean room, hospital, etc.

|

|

Service

|

25 years

|

Application of rock wool board

Rock wool sandwich panels are widely used for roofing, wall and partition of steel structure workshop, simple movable room and air cleaning room.

Why Choose Us?

1. High-quality Raw Materials

We strictly select high-quality suppliers. All color steel coils and core materials are from China’s top 500 companies and have undergone strict quality inspections to ensure the basic quality of the products.

2. Advanced Production Equipment

Our factory is equipped with advanced production equipment, including automated production lines, CNC cutting machines and high-precision pressing equipment, to ensure that the production process of each color steel sandwich panel is accurate and stable.

3. Mature Supply Solutions

All accessories for installing sandwich panels are provided in one stop, and the standardized packaging process can prevent the sandwich panels from being rubbed or damaged during transportation, making it easy for customers to unload the vehicles, saving time and money for customers.

We provide one-stop sandwich panel installation, a variety of accessories and accessories, and come with installation drawings and video guidance, saving you time and money. And our products are made of environmentally friendly materials, and the production process follows environmental standards, committed to reducing the impact on the environment. Color steel sandwich panels are recyclable and meet the requirements of modern green buildings.