Description

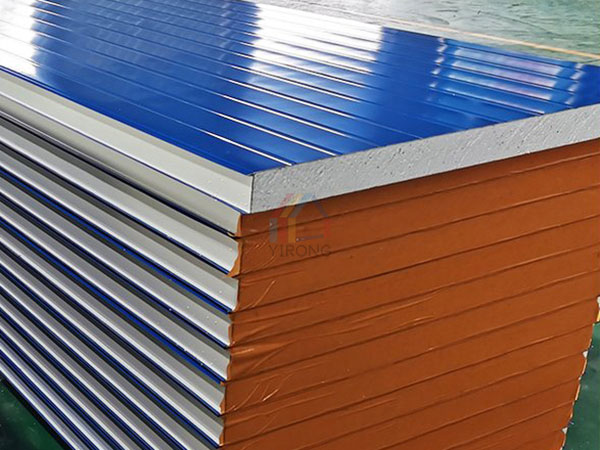

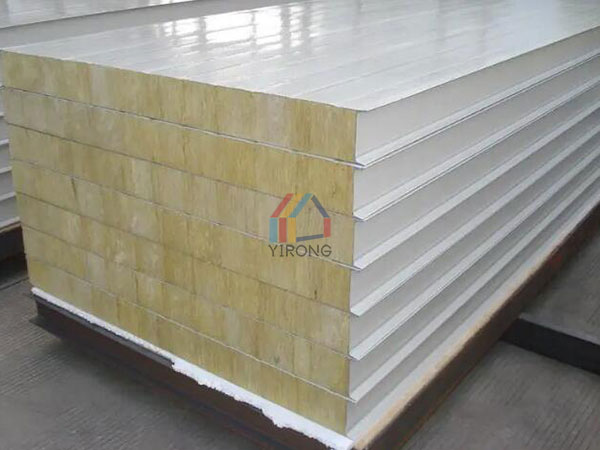

Color steel sandwich panel is a common product in current building materials, which is not only good in flame retardant and sound insulation, but also environmentally friendly and efficient. The color steel sandwich panel is formed by pressing the upper and lower metal panels and the middle polymer heat insulation core. It has the characteristics of easy installation, light weight, environmental protection and high efficiency. Moreover, the closed-cell molecular structure used in the filling system can prevent the condensation of water vapor.

The color steel sandwich panel is composed of two layers of formed metal panels (or panels of other materials) and a polymer heat-insulating inner core directly foamed and cured in the middle of the panels. These finished sandwich panels are easy to install, lightweight and efficient. The filling system also uses a closed-cell molecular structure, which can prevent the condensation of water vapor.

The forming of the outer layer steel plate fully considers the structure and strength requirements, and takes into account the aesthetics, and the inner surface layer is formed into a flat plate to meet various needs.

Classification

There are six types of core materials:

Polystyrene sandwich panel (EPS sandwich panel, which is the most widely used variety on the market);

Extruded polystyrene sandwich panel (XPS sandwich panel);

Rigid polyurethane sandwich panel (PU sandwich panel);

Three polyester sandwich panels (PIR sandwich panels);

Phenolic sandwich panel (PF sandwich panel);

Rock wool sandwich panel (RW sandwich panel).

There are two types of panels:

Metal panel and non-metal panel. Metal panels are easy to process and can be made into various shapes. However, in some cases, non-metallic panels have functions that metal panels cannot, such as corrosion resistance and impact resistance.

Scope of application

Color steel sandwich panels are widely used in large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storages, mobile rooms, building layers, clean workshops and places that require thermal insulation and fire prevention. The sandwich panel is beautiful in appearance, bright in color and good in overall effect. It integrates load-bearing, heat preservation, fire prevention and waterproofing, and does not require secondary decoration. It is fast and convenient to install, has short construction period and good comprehensive benefits. It is a widely used, extremely Potential high-efficiency and environmentally friendly building materials.

|

Panel Thickness |

50mm/75mm/100mm/150mm/200mm (other customized thickness is also acceptable) |

|

Effective Width |

950mm/ 1000mm/ 1150mm(wall) ; 950mm/1000mm(roof) |

|

Length |

Customized as customer’s request, but max 11.8m because of container shipment |

|

Insulation Core Type |

Polystyrene(eps) (Density 8kg/m3~20kg/m3) |

|

Compound Details |

External Layer: color steel sheet, 0.3mm~0.8mm available |

| Middle insulation: sandwich panel, 50mm/75mm/100mm/150mm/200mm | |

| Internal Layer: color steel sheet, 0.3mm~0.8mm available | |

|

Surface Color |

Standard is off-white (RAL9002) or sky blue(RAL5015). Other colors also can be customized but need a quantity bigger than 500sqm. |

|

Thermal Conductivity |

0.035-0.05W/m.k |

|

Lifetime |

≥15 years |

|

Advantages |

Lightweight; Waterproof; Good insulation performance with competitive price |

|

Applications |

Widely used as wall/roofing materials for Office; Warehouse; Workshop; Poultry House; Planting Room; Shelters; Cleanroom Etc. |