Description

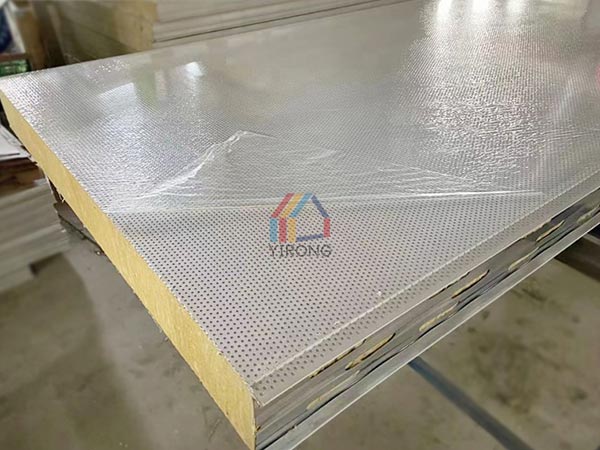

PU sandwich panel is also called polyurethane sandwich panel, polyurethane color steel sheet and polyurethane color steel sandwich panel. The product characteristics of polyurethane sandwich panel also have various advantages of pu, and it has low thermal conductivity, good load resistance, high bending strength, no water absorption, no decay, no insect bite, and is not easy to burn. It has small shrinkage and no embrittlement under ultra-low temperature. It is most suitable for cold storage panels.

Pu panel: thermosetting polyurethane elastomer is called PU for short, and its name is casting polyurethane. It is commonly known as Youli glue and spring glue. It is formed by the reaction of polymer polyol and isocyanate, chain extension and crosslinking. It is a new synthetic material between plastic and rubber. According to the different main chain structure of polyurethane elastomer, it can be divided into polyether type and polyester type.

Polyether polyurethane: polyether polyurethane occupies the most important position in polyurethane, mainly because of its low viscosity and convenient operation. Polyether is superior to polyester in resilience, moisture evaporation, low temperature performance, impact strength, heat accumulation, water resistance and mold resistance.

Polyester polyurethane: compared with polyether, its mechanical strength, tensile strength, tear strength, sliding friction, oil resistance, thermal aging, adhesion to metal, solvent resistance and oxidation resistance are better than polyether. However, polyester has high viscosity and is difficult to operate.

Specifications:

| The technical standard of PUR panel | ||||

| No. | Item | Unit | Tel. Requirment | |

| 1 | Density | kg/m3 | 40±2 | |

| 2 | Heat conductivity | W/m.k | <= 0.024 | |

| 3 | Compresive strength | KPa | ≥ 150 | |

| 4 | Combustion performance |

Average buring time | s | <= 90 |

| Average buring range | mm | <= 50 | ||

| 5 | The bond strength between core layer and steel | Mpa | ≥ 0.1 | |

| The technical standard of PIR panel | ||||

| No. | Item | Unit | Tel. Requirment | |

| 1 | Density | kg/m3 | 45±2 | |

| 2 | Heat conductivity | W/m.k | <= 0.022 | |

| 3 | Combustion performance | B1 | ||

| 4 | Strippingl performance |

The core material on the surface | Uniform distribution | |

| The adhesive area of each stripping surface | ≥ 90% | |||

| 5 | The bond strength between core layer and steel | Mpa | ≥ 0.1 | |

Polyurethane color steel sheet material

Upper / lower steel plate: the thickness is 0.4~1.2mm, and the types include color steel plate, electric / hot galvanized plate and stainless steel plate.

Core material: polyurethane (PU) unit weight is 30~80 kg /m3.

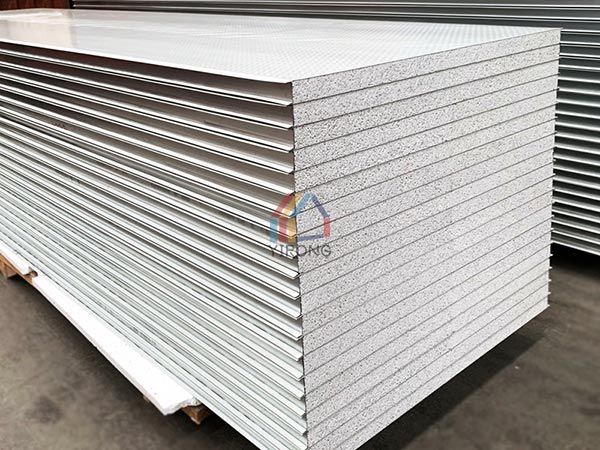

Pu sandwich panel product specification:

1. Conventional width of machine-made plate: 1150mm, 950mm; Thickness: 40mm ~ 250mm; Unlimited length.

2. Conventional width of manual plate: 1180 ㎜; Thickness: 40mm ~ 250mm; Unlimited length

| Panel Thickness | 50mm/75mm/100mm/150mm/200mm (other customized thickness is also acceptable) |

| Effective Width | 1000mm / 1m(wall) ; 1000mm / 1m(roof) |

| Length | Customized as customer’s request, but max 11.8m because of container shipment |

| Insulation Core Type | Polyurethane(PU/PIR) (Density 40kg/m3) |

| Compound Details | External Layer: PPGI steel sheet, 0.4mm~0.8mm available |

| Middle insulation: PU/PIR board, 50mm/75mm/100mm/150mm/200mm | |

| Internal Layer: PPGI steel sheet, 0.4mm~0.8mm available | |

| Surface Color | Standard is off-white (RAL9002) or sky blue(RAL5015). Other colors also can be customized but need a quantity bigger than 500sqm. |

| Thermal Conductivity | ≤0.025W/m.k |

| Lifetime | ≥15 years |

| Advantages | Lightweight; Waterproof; Best Insulation Building Material |

| Applications | Widely used as wall/roofing materials for Planting Room, Cold Room(Cold Storage), Breeding Farm, Constant Temperature Laboratory Etc. |

Application area

The sandwich panel has beautiful appearance, bright color and good overall effect. It integrates load-bearing, heat preservation, fire prevention and waterproof. And without secondary decoration, the installation is fast and convenient, the construction period is short, and the comprehensive benefit is good Pu sandwich panel is a kind of high efficiency and environmental protection building material with wide application and great potential. Polyurethane sandwich panels are widely used in large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storages, activity rooms, adding floors to buildings, ceilings and partitions of air clean rooms, and places requiring thermal insulation and fire prevention.

Product characteristics

Polyurethane elastomer has good properties such as chemical corrosion resistance, tensile strength, high elasticity, high pressure load resistance, high wear resistance, strong shock absorption, tear resistance, radiation resistance, high strength, high load bearing, shock absorption and cushioning. High elasticity can be maintained in a wide hardness range (Shore A10 to shore d75). Its excellent and unique comprehensive properties are not possessed by ordinary plastics and rubbers.

We provide one-stop sandwich panel installation, a variety of accessories and accessories, and come with installation drawings and video guidance, saving you time and money. And our products are made of environmentally friendly materials, and the production process follows environmental standards, committed to reducing the impact on the environment. Color steel sandwich panels are recyclable and meet the requirements of modern green buildings.

FAQ

1. You are manufacture factory or trading company?

We are manufacture factory. You are welcomed to visit us at any time. In the workshop,it has a complete advanced equipment system for making steel structures and panels. So we can make sure the good quality and also the competitive price.

2. How about your quality control?

Our products have passed CE EN1090 and ISO9001:2008.

3. Can you offer design service?

Yes,we have an engineer team and can design for you according to your requirements.Architectural drawing,structure diagram,processing detail drawing and installation drawing will be made and let you confirm in different time of the project.

4. What’s the delivery time?

The delivery time depends on the size and quantity of building.Generally within 30 days after receiving the payment.And partial shipment is allowed for big order.

5. Do you offer service for installation?

We will furnish you the detailed construction drawing and the construction manual which could help you to erect and install the building step by step. We also could send the engineer to your local to help you if neede.

6. How to get a quote from you?

You can contact us online or by email.If you have drawings, we can quote them according to your drawings.Or else please let us know length, width, eave height and local weather to give you an exactly quotation and drawings.

7. What’s the payment term?

30% deposit and 70% balance before shipment.