Description

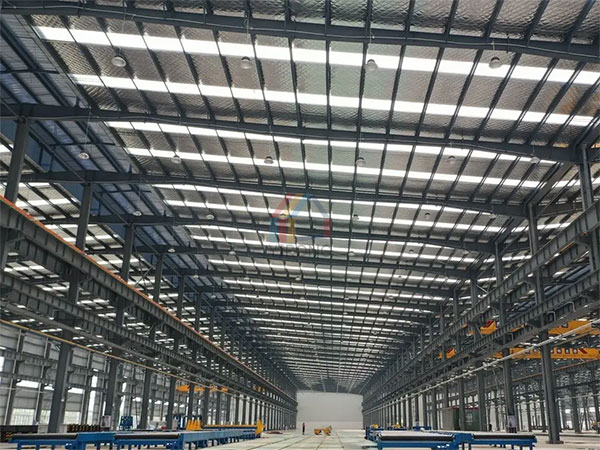

The metal frame factory shed is the preferred combination of profile steel and color steel plate, which is made of welding, bolt connection and riveting. The steel structure shed is one of the factory building types which takes the metal frame as the main structure and forms the structure through welding.

Steel frame refers to a structural shape that can bear and transfer loads by connecting thin steel plates and hot rolled, cold formed or welded sections through connectors. The steel structure building system has the comprehensive characteristics of light deadweight, fast installation, short construction period, good seismic performance, fast investment recovery and less environmental pollution. Compared with concrete structure, it has more unique advantages in the development of “high, large and light”. In the global scope, the steel structure shed has been reasonably and widely used in the field of construction engineering.

Compared with concrete buildings, steel structure industrial shed buildings in industrial plants have advantages in use, design, construction and comprehensive economy.

Advantages of metal frame factory shed

a. It has low cost, can be relocated at will, and can better meet the large span space.

b. By reducing the section area of columns and using light wallboards, the area utilization rate is improved, and the indoor effective use area is increased by 6%.

c. The energy-saving effect is good. The wall is made of light energy-saving standard C-shaped steel, square steel and sandwich plate, which also has thermal insulation performance.

The construction of steel structure shed is mainly divided into the following five parts:

1. Embedded parts: components that can stabilize the plant structure and bearing capacity.

2. Column: H-shaped steel and angle steel frame column are generally used for combined connection.

3. Beam: most of them are composed of angle steel frame and H-shaped steel (the height of intermediate product depends on the span of the beam).

4. Purlins: now they are usually composed of C-shaped steel and galvanized C-shaped steel (previously, angle steel and reinforcement were used together).

5. Tile: There are two kinds, the first is single tile (color steel tile). The second type is composite board (polyphenylene, rock wool, polyurethane) with foam placed between two layers of tiles to warm in winter and cool in summer, which also has sound insulation effect.

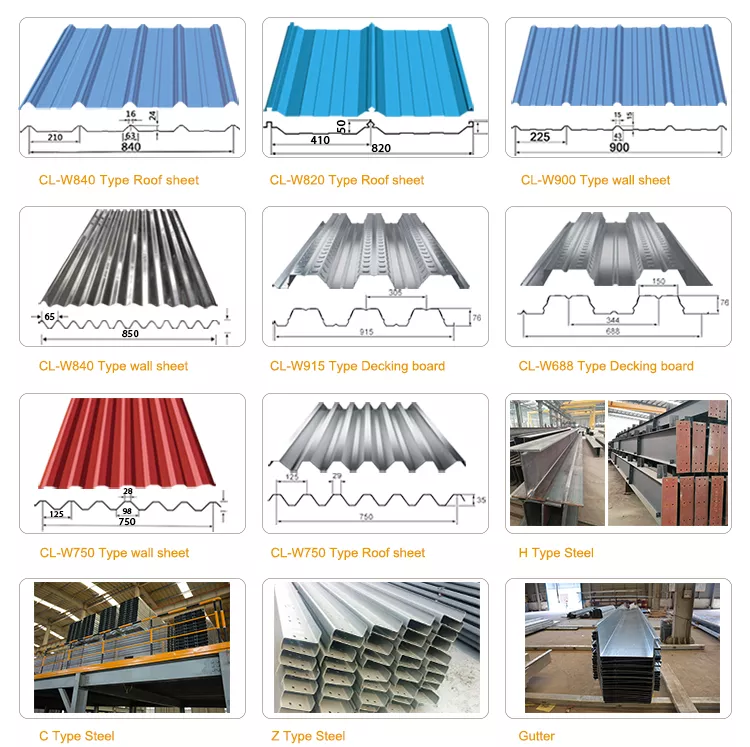

Steel Structure Industrial Shed Building Parts

| Main Structure | Welded H Section or Hot Rolled H Section Steel |

| Purlin | C Section or Z section, Q235B, Q345B |

| Cladding system | Sandwich panels for wall and roofing, single sheets for wall and roofing |

| Roof/Wall Caldding | Corrugated Plate or Sanwich panels for fireproof, insulation requirements, can choose EPS,PU/PIR,Rock Wool sandwich panels |

| Brace | Q235B/Q345B Round Steel Tube/Angel steel/steel pipe |

| Tie Bar | Q235B/Q345B Round Steel Tube |

| Roof gutter | Galvanized color sheets or SS steel |

| Parapet | Designed as the customers’ requirements. |

| Rain Spout | PVC pipes |

| Covering/Flashing | Bending parts from the galvanized color sheets to cover the edges. |

| Windows | Glass curtain, normal windows, Plastic windows, Aluminum Alloy windows, double glazed windows, fixed windows, opened windows, as your requirements |

| Skylight | PVC Skylight Panels |

| Ventilation | Ventilators, louvers |

| Doors | KFC doors, Glass doors, Swing door, Fire Exit doors, sandwich sliding doors, rolling doors, Electric rolling doors |

| Connectiong | High strength Bolts, Normal Bolts, Anchor bolt |

| Packings | Suitable for shipping packaging, pallets, 40HQ, 40GP, according to your requirements. |

| Accessories | All screws, sealant, glue |

Material Structure