Description

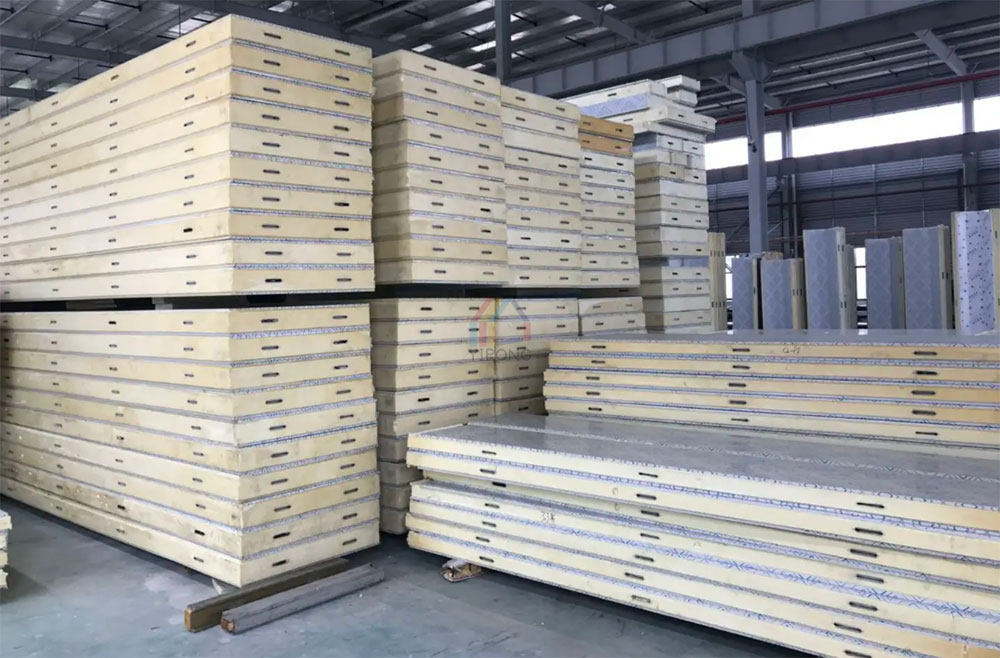

Cold room panels are generally prefabricated by manufacturers and have a fixed length, width and thickness. High and medium temperature cold storage generally use 100mm thick plates, low temperature storage and freezing storage generally use 120mm or 150mm thick plates. Therefore, if it is not the predetermined cold storage panel, pay attention to the density of the cold storage board and the thickness of the steel plate when purchasing. The thickness of the steel plate of the regular manufacturer is generally above 0.4mm, and the foaming density of the cold room panel is 38kg-40kg/m³ per cubic meter according to the national standard.

The three important factors of the cold room panels are the density of the cold storage panel, the thickness and load-bearing capacity of the steel plates on both sides. The density of the cold storage insulation panel is high, so the foaming of the board is to increase the amount of polyurethane, and at the same time increase the thermal conductivity of the polyurethane panel, which will reduce the insulation performance of the cold room board and increase the cost of the board.

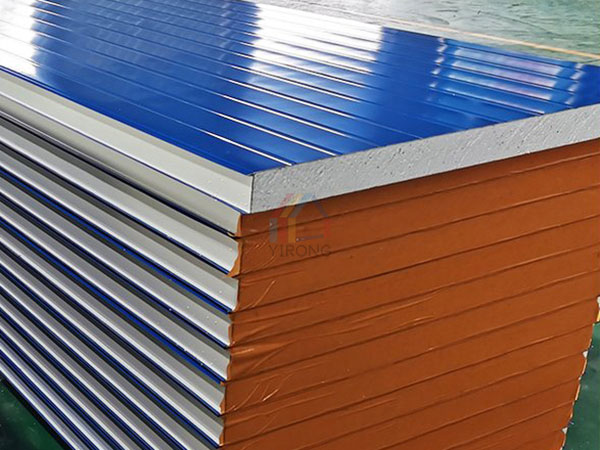

| Type | Polyurethane Sandwich Panels(PU, PUR, PIR) |

| Panel Material | Color steel sheet, Galvanized steel, Stainless steel sheet, or other. |

| Place of Origin | China |

| Length | Customize( At most 23meters) |

| Effective Width | 960mm(cam-lock); 1120mm( Fast-ft) |

| Core thickness | 50mm, 75mm, 80mm, 100mm, 120mm, 150mm, 200mm |

| Features | Insulation,Soundproof, fireproof, waterproof |

| Certificates | SGS, ISO14001, ISO9001 |

| Color | White, Gray, Sliver, Whit gray…etc, as required |

| Lifetime | 10-30 years |

| Fire proof rate | B1, B2 |

| Usage | In different fields: Food storage, Lab center, Medicine factory, Logistics Center, Cold Drinks Processing Center |

If the foaming density is too low, the load-bearing capacity of the cold storage board will decrease. After testing by relevant departments, the foaming density of the polyurethane cold storage insulation panel is generally 35-43kg/m3 as the standard. Some manufacturers have reduced the thickness of the color steel plate in order to reduce the cost. The reduction of the thickness of the color steel plate will directly affect the service life of the cold storage. When selecting the cold storage panel, the thickness of the color steel plate of the cold room panel must be determined.

Polyurethane cold storage boards use lightweight polyurethane as the inner material of the cold room panels. The advantage of polyurethane is that it has very good heat insulation performance. The exterior of the polyurethane cold storage board is made of SII, pvc color steel plate and stainless steel plate components. The advantage of this is to prevent the cold room panel from spreading the temperature due to the large temperature difference between the inside and outside, so that the cold storage can save more energy and improve the working efficiency of the cold storage.

The choice of polyurethane cold storage board is very important for cold room. Because cold storage is different from ordinary warehouses, the temperature inside cold storage is generally relatively low, and the requirements for air temperature, humidity, and environment are relatively high. Therefore, when we choose polyurethane cold room panels, we must pay attention to choosing polyurethane cold storage panels that are better for temperature control. If the choice of polyurethane cold storage board is not good, it is difficult to control the temperature in the cold storage, which will easily lead to the deterioration of the products stored in the cold storage, or make the refrigeration compressor of the cold room work frequently, waste more resources and increase costs. Choosing the right plate can better maintain the cold storage.

Applications:

| Thickness of Sandwich Panel | Application Temperature |

| 50mm | ≥ 5°C |

| 75mm | ≥ -5°C |

| 120mm | ≥ -15°C |

| 150mm | ≥ -25°C |

| 175mm | ≥ -35°C |

| 200mm | ≥ -45°C |

| 250mm | ≥ -55°C |

Features of cold room panels

1. The rigid polyurethane of the cold storage board has low thermal conductivity and good thermal performance. When the density of rigid polyurethane is 35-40kg/m³, the thermal conductivity is only 0.018-0.024w/(m.k), which is about half of that of EPS, which is the lowest thermal conductivity among all current insulation materials.

2. Rigid polyurethane has moisture-proof and waterproof properties. The closed cell rate of rigid polyurethane is more than 90%, which is a hydrophobic material, which will not increase the thermal conductivity due to moisture absorption, and the wall will not seep water.

3. Rigid polyurethane is fireproof, flame retardant and high temperature resistant. Polyurethane is a flame retardant self-extinguishing material after adding a flame retardant. Its softening point can reach more than 250 degrees Celsius, and it will only decompose at a higher temperature. In addition, when the polyurethane of the cold storage panel burns, it will form carbon deposits on the surface of its foam. This layer of carbon deposits can help isolate the foam below and effectively prevent the flame from spreading. Moreover, polyurethane does not produce harmful gases at high temperatures.

4. Due to the excellent heat insulation performance of polyurethane sandwich panel, under the same heat preservation requirements, the thickness of the building’s outer protective structure can be reduced, thereby increasing the indoor space.

5. Polyurethane cold storage board have strong deformation resistance, are not easy to crack, and have stable and safe finishes.